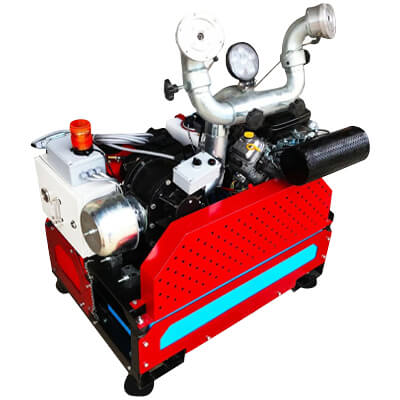

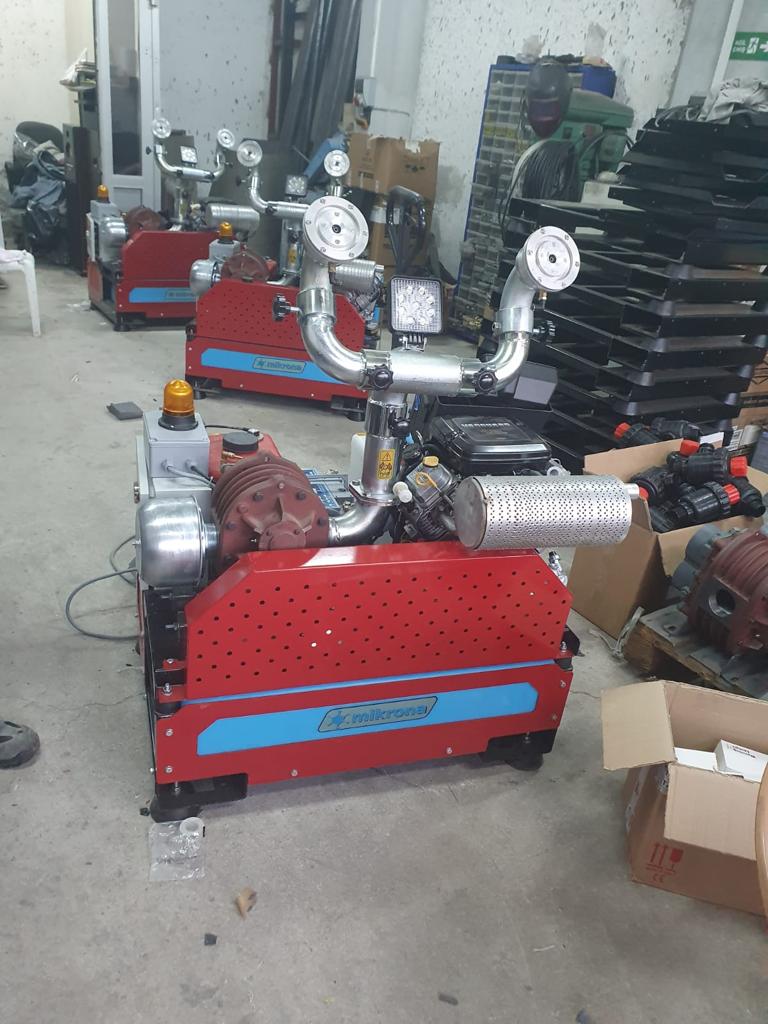

Next Generation ULV

The vehicle mounted ulv (cold fogging) machine that we produce is the U.L.V. It complies with the specifications for (ultra low volume) devices. U.L.V. It is an aerosol mist that creates an extremely fine spray technique. It provides a superior, permanent, effective and most economical struggle with the least active substance in destroying the pests. Our machine, which is completely domestic production, has flow measurements made by Tamtest center and has TS 12659 Service Adequacy Certificate. It has 2 (two) years of manufacturing and 10 (ten) years of spare parts and service warranty.

ADVANTAGES

• Powerful quiet economical Briggs Vanguart engine.

• High efficiency maintenance free blower.

• Ergonomic design that can be easily mounted on the vehicle.

• Tank made of stainless steel.

• Uninterrupted flow with gear pump

• 0-1000 ml/min adjustable flowmeter.

• 360 degree horizontal and vertical adjustable nozzle

system.

• Ease of use at night with the LED lighted control panel.

• Hose and steel fittings made of Teflon material

with long-lasting use.

• Always available spare parts and inexpensive maintenance

repair possibility.

• Channel spraying system.

• Single, double and quadruple nozzle types upon request.

• Wired and wireless control option

TECHNICIAL SPECIFICATIONS

General;

1.The engine has a battery charging system and the first start is made with the starter motor.

2.Stainless connection equipments are used in device connections.

3.The electrical system of the device has a system that is resistant to outdoor conditions.

4.All parts of the device that come into contact with the pesticides are made of corrosion-resistant materials.

5.There is an indelible label on the visible face of our devices, indicating the features of the relevant device.

6.ULV has a design that can be mounted together with the Sprayer.

7.The droplet diameter and distribution of the device are in the standards determined by the World Health Organization (WHO) and their documents obtained from authorized institutions (TAMTEST) and organizations (relevant departments of universities or the Ministry of Agriculture).

Engine;

1.It has a four-stroke, twin-cylinder, gasoline-powered engine.

2.The engine has 18 HP power.

3.It is starter, charged and air cooled.

4.The engine gets its first start from the starter and is powered by a 12 V battery with a power of at least 60 amps.

Fuel and Solution Tanks;

1.Solution tanks are made of polyethylene material.

2.The pesticide tank capacity is 100 liters and this feature has been documented by an accredited laboratory.

3.It has a float clock system to measure the liquid volume.

4.Solution Tanks have relief valves at the bottom for cleaning.

5.The fuel tank has a capacity of 35 liters and is made of polyethylene material.

Spray Head;

1.The spray head is made of corrosion resistant aluminum material and has two or four spray heads.

2.The nozzles can be manually moved left and right and up and down.

3.The spray nozzles produce an average of 20-25 µm droplet diameter and are certified by TAMTEST for the calibration of pesticides authorized by the relevant ministry.

4.Withstands high pressures

Blower (Compressed Air Bellows);

1.The blower system is positive displacement roots rotary type.

2.The blower working pressure produces a minimum of 6 m3 of air at at least 1750 (± 50) rpm and the minimum pressure is 4-5 PSI.

3.The blower system provides its movement from the gasoline engine with double pulleys and “V” type double belts.

4.There is an oily manometer on the blower that shows the pressure.

Pesticide Flow System;

1.Pesticides and washing flow is provided by a 12 V direct current gear pump system.

2.Flow rate can be adjusted 0-1000 ml/min.

3.It has leak-proof gaskets made of chemical resistant viton material.

4.It is resistant to long working hours.

Filter;

1.There is a pesticide and chemical resistant wire filter of the L.V system that can be cleaned when necessary.

2.The filter eliminates particles up to 100 µm in diameter.

Control System;

1.All functions of the device are controlled by the remote control.

2.The remote is wired; There is also a wireless option.

3.At least 5 meters it has a long cable.

4.There is an on-off button on the remote, as well as a ULV start button and a device wash button.

5.There is at least 1 lighting and overhead lamp behind the nozzle that will show the spray amount of the device.

6.In order to understand the engine operation, the lubrication warning light is located on the control.

Weight and Size;

1.The empty weight of the device is 220 Kg.

2.The chassis can be installed on all double cab pickup trucks, regardless of brand.

3.The width of the ULV is 700 mm, the length is 950 mm, and the height is 1500 mm; These measurements are certified by official institutions.

4.The chassis is 3 mm thick.

Certificate:

1.It complies with the Regulation on Plant Protection Tools and Machines No. 27893 published in the Official Gazette dated 04.2011.

2.The device has the TAMTEST report prepared by the Ministry of Food, Agriculture and Livestock.

3.The manufacturer has a CE certificate for the machine.

4.It has a two-year manufacturer’s warranty.